When I first took over the business from my father almost 20 years ago, our team was sharing one giant Excel spreadsheet to do our supply chain planning. The spreadsheet could only be updated by one person at a time, causing obvious limitations to our team’s efficiency. One of my first initiatives was to implement an ERP software, which we upgraded a few years ago. We started a software division in 2018 and have worked on several logistics software projects, including building a trucking management software. Here’s a few lessons we’ve learned along the way.

73% of Enterprises Use Spreadsheets for Supply Chain Planning

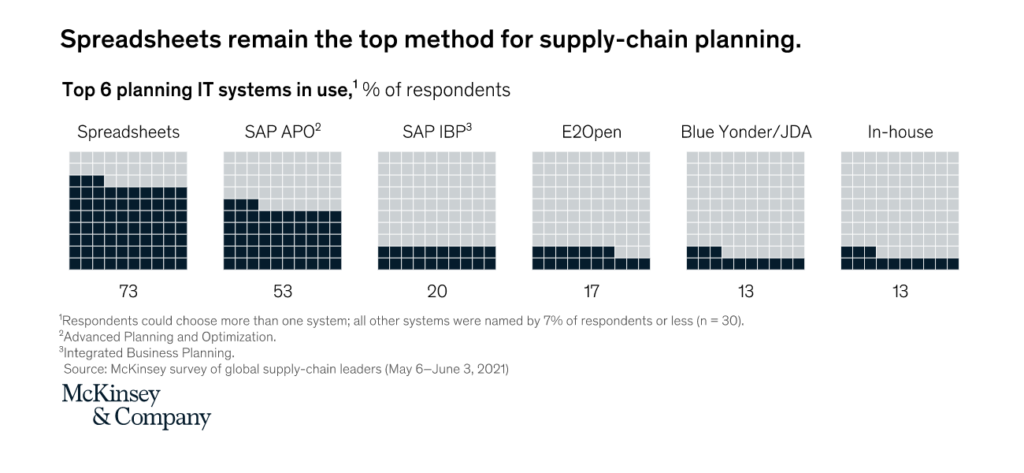

According to a recently McKinsey & Company study, a surprising majority of enterprises use manual or outdated IT systems to do their supply chain planning. 73% of respondents still use spreadsheets, and 53% use SAP Advanced Planning and Optimization (APO), which is an antiquated supply chain planning application that SAP will stop supporting in 2027.

Supply-chain leaders are aware that their current methods need to be changed and 90% plan to implement a new solution in the new 5 years. But implementing a new IT system is costly and has many risks.

The Challenges of Upgrading Your Supply-Chain IT System

Companies hold onto older systems longer than they want because replacing them requires a major investment of time and money. Here are a few statistics according to McKinsey’s recently article, “To improve your supply chain, modernize your supply-chain IT”:

- Companies average 2.8 years to implement a new IT system (from vendor selection to complete rollout)

- Industries with complex supply chains take 4-6 years and $62 to $125 million to fully implement a new supply-chain planning system

- Vendor selection is critical and difficult, with most companies evaluating two to eight vendors

- 45% of executives said the biggest barrier was a lack of consensus of a new system’s technical and process requirements

- 35% of executives said new planning systems that were implemented did not meet expectations

- 28% of executives struggled to create a compelling business case for switching to a new system

3 Steps to Successfully Implement a New Supply-Chain Planning IT System

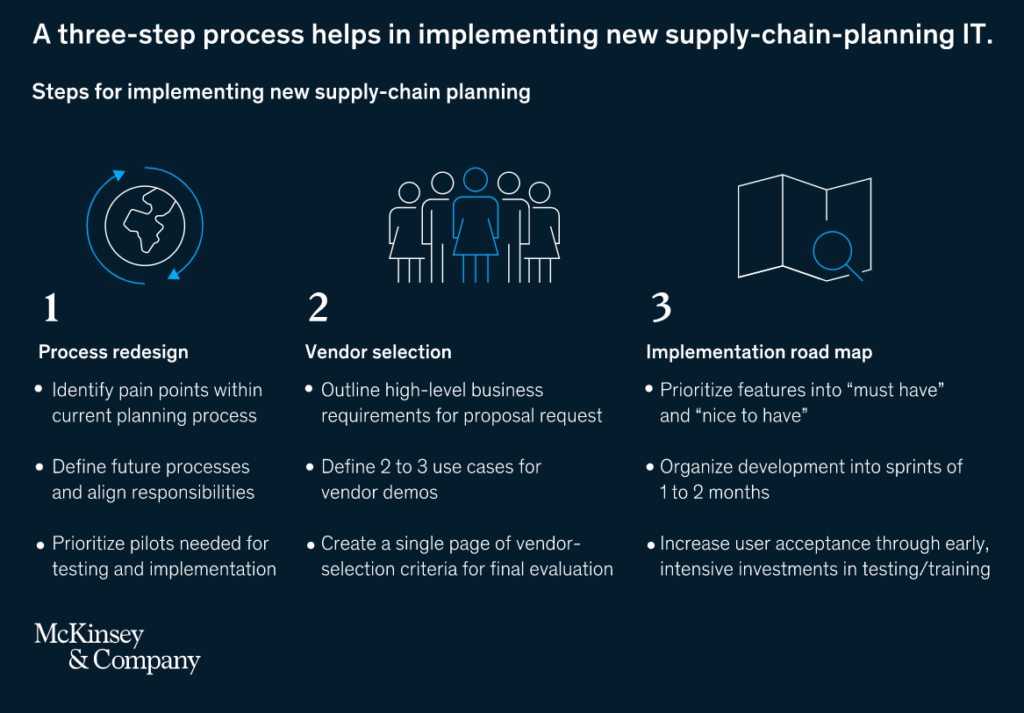

60% of IT implementation failures are due to one of these three reasons: they aren’t completed on time, they are over budget, or they don’t meet expectations. McKinsey has outlined a clear 3-step process for implementing new supply chain-planning that clearly addresses these failings.

A few additional pieces of advice from McKinsey to keep in mind during implementation of a new system are:

- Keep the customer at the center of the change

- Train in-house personnel to work on the system

- Use a mix of in-person and online learning.

If you are considering modernizing your supply-chain IT system, we encourage you to read the full article on McKinsey’s website.

Canaan Group’s Software Division

In 2018, we launched a new division at Canaan Group that specialized in creating efficiencies for our clients through customized technology services. The vision is to provide in-depth software solutions to complement our supply chain services.

With the rapid advancement of technology, many leaders are asking how technology can be used in their businesses to improve efficiency. Our team at Canaan Group has benefitted from implementing technologies like an ERP system and online trucking reservation system, which we have customized or built for our own use. We’ve been able to offer our expertise to our clients in providing customized technologies that make their operations simpler, more efficient, and automated.

Source:

To improve your supply chain, modernize your supply-chain IT, McKinsey & Company, February 9, 2022. Accessed Mar 21, 2022.